Prosthetic Arm

Prosthetic Arm; designed in OpenSCAD and Onshape, printed on a Bambu p1s,

heavily inspired by Kwawu arm by Jacquin Buchanan

(You Probably Don’t Recognize Me Because of the Red Arm)

I presented on applications for 3D printing in medicine during RSLS 2025 (abstract is under upcoming). Seeing as I could not expect my audience to have handled 3D printed objects before, and also because I thought it would make a cool showpiece, I built this arm. The design is based on Jacquin Buchanan’s Kwawu arm, with significant modification to his whipple mechanism (I couldn’t get his to work), remodeling of the hand (for largely aesthetic reasons), and edits to the flexible TPU parts to make them print with my more rigid 95A TPU.

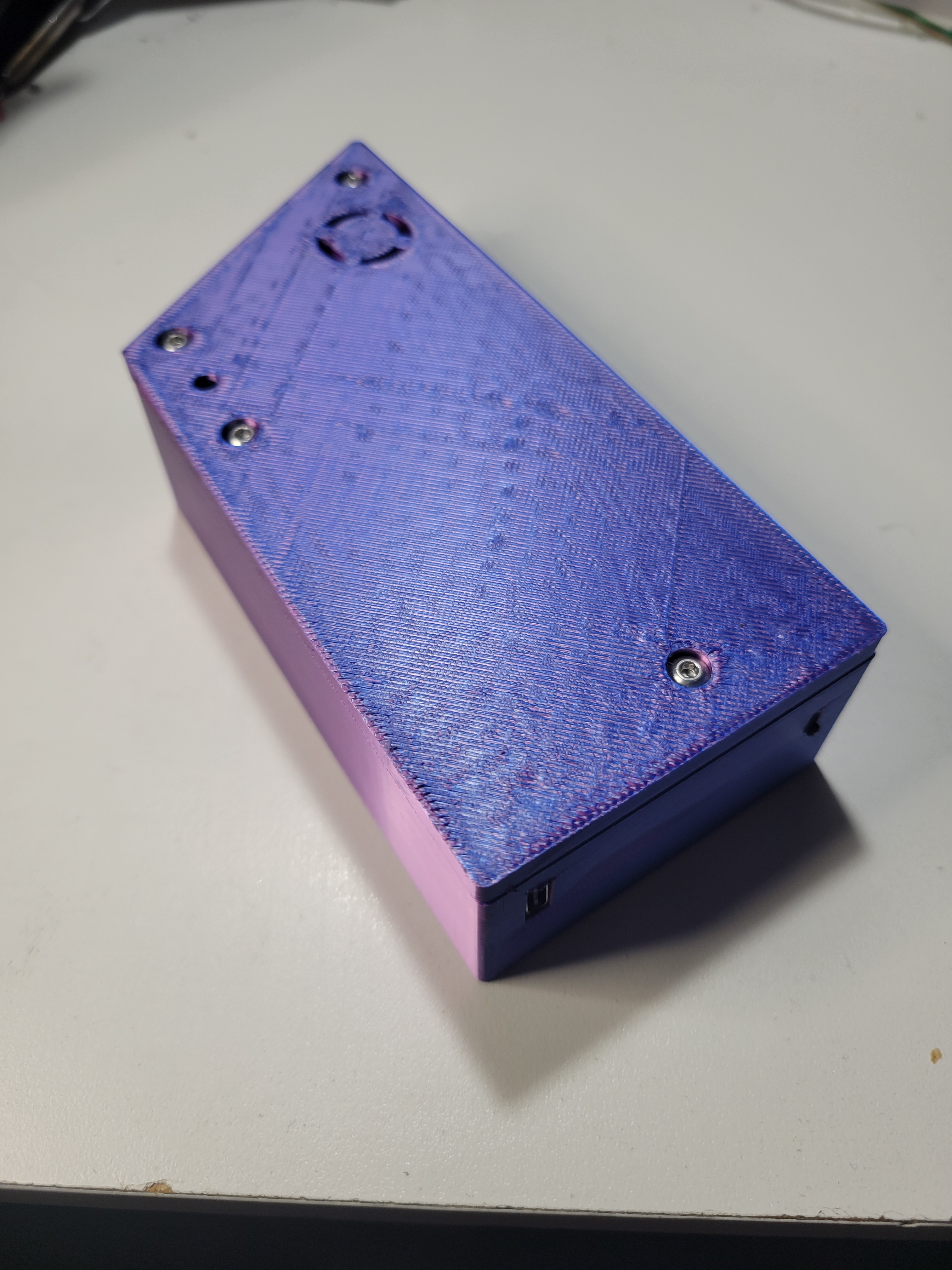

ViThermo™

ViThermo; designed in Onshape, printed on a Bambu p1s, programmed in Arduino

My friend didn’t know if her lunch was safe to eat after sitting in her lunchbox for hours. The solution? ViThermo! An esp32 circuit to monitor the temperature inside her lunchbox and measure the time her food was in unsafe temperatures (between 5 and 60 degrees C), then change a status LED depending on how safe it is to eat.

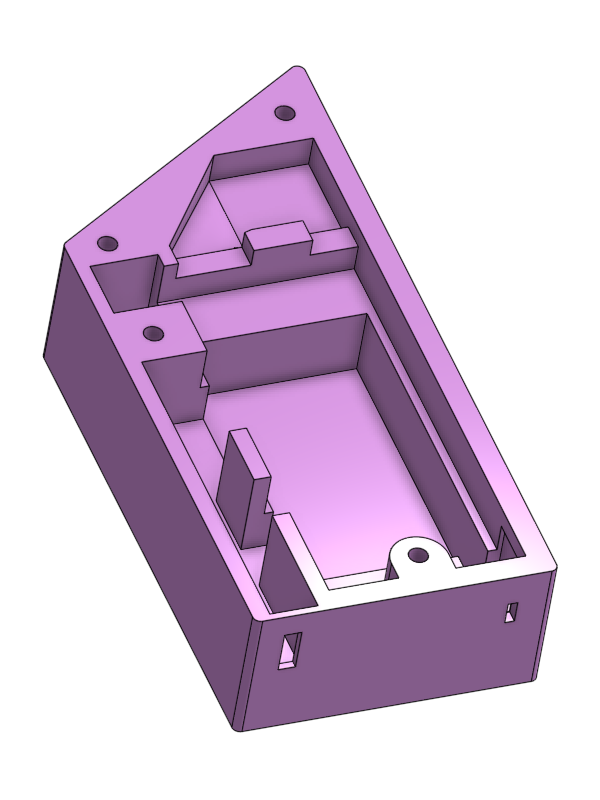

Jacktyl Manuform™

Jacktyl Manuform; designed with OpenSCAD and Onshape, printed on a heavily modded Ender3, Programmed with QMK

My take on the dactyl manuform keyboard design, optimized for my big hands and my uniquely (at least among the mechanical keyboard community) varied computer use which requires function keys and other things not often found in specialized keyboards, warranting a custom design.

CAD was handled via OpenSCAD for the most part, with the microcontroller mount and other tweaks done in Onshape. Electronically, the design relies on two pro micros, one per half, communicating with each other via an aux cable. Software was also simplified by using a tool called QMK to generate the firmware.

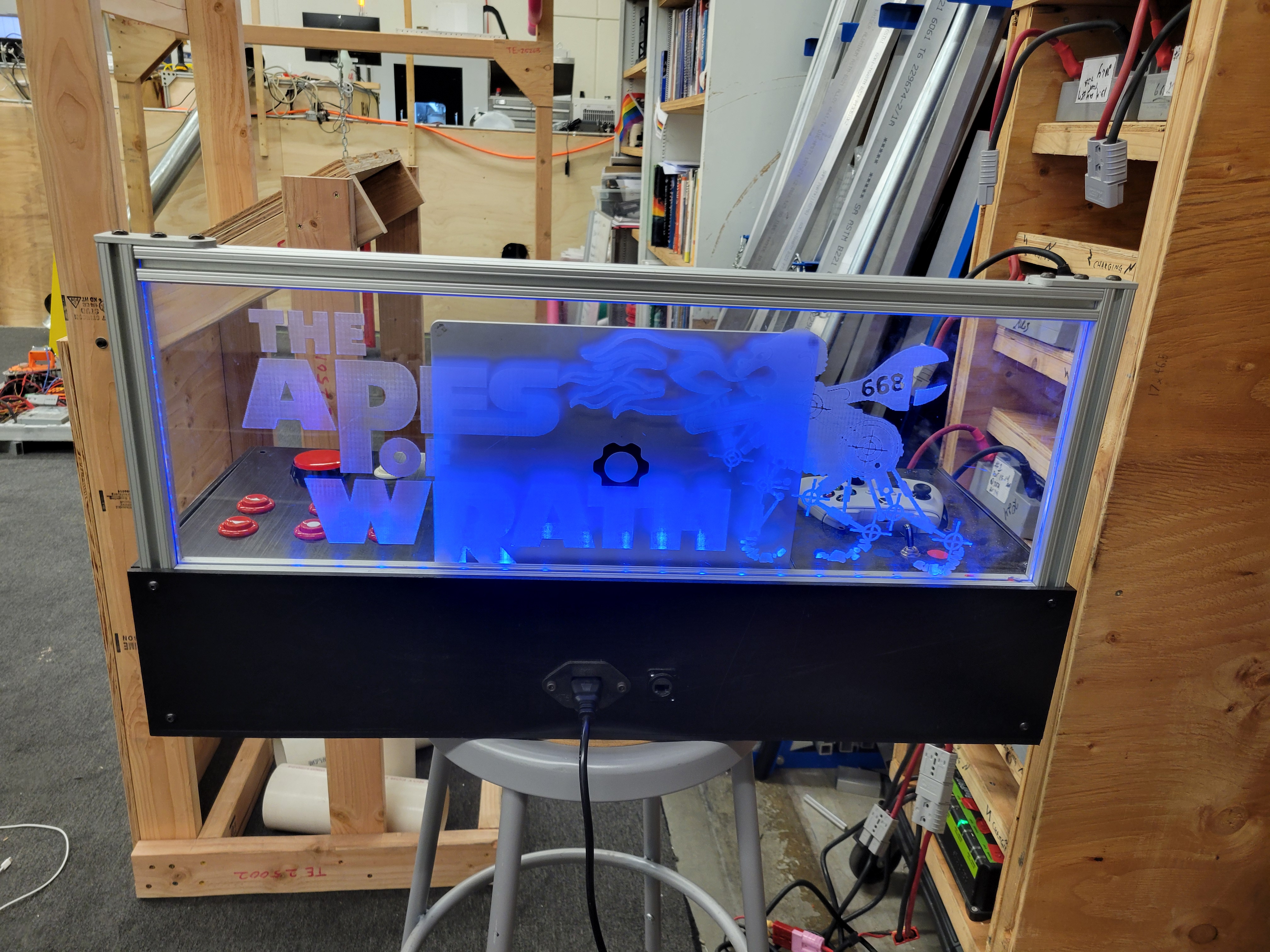

CHIMP™

CHIMP; designed in Onshape, programmed in Arduino

On my robotics team, The Apes of Wrath, we had problems with our method of controlling our robot. This warranted a completely new, robust approach to how we control the robot. Another important consideration is how we package the whole system to make it easy to move around and set up at competitions.

My new design consists of a lightweight frame made of aluminum extrusion, POM panels, banandles™ (banana handles) with yellow grip tape for comfort, and an acrylic back window with our team’s logo laser etched, lit from below with an LED strip that shows our alliance color (either red or blue at competition). The custom arcade style button panel consists of a matrix of switches wired up to an arduino that emulates a USB device for easier compatibility with our robot code.

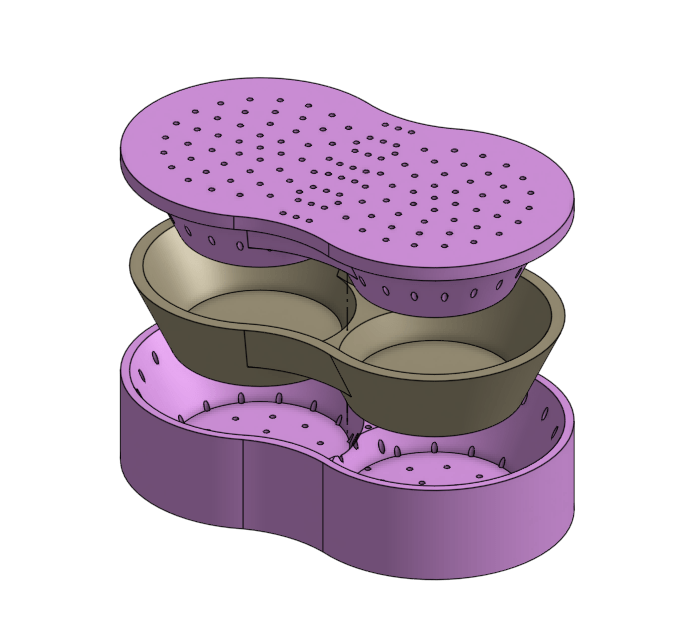

PhilBox™

PhilBox; designed in Onshape

I bought some egg bites at a coffee shop on my way to class, and they stuck to the flimsy cardboard tray they were served on. My solution was to redesign their tray to not only be non-stick but to be compostable as well. My design uses molded pulp for the main structure, while relying on a thin beeswax coating to keep the egg bites from sticking.